Even more wind turbine blades will soon prove their strength at the port of Aalborg. This became clear when Aalborg Havn A/S entered into an agreement with the BLAEST test centre to build a large test facility in Aalborg East on the land next to the company’s existing test centre. The land is owned by Aalborg Havn A/S but rented out to its subsidiary, NTC Ejendom A/S, which is the developer of the project.

The aim of the new test facility is to meet the increasing demand for blade testing resulting from intensified focus on wind energy in recent years. BLAEST’s recent agreement with Danish wind turbine manufacturer Vestas was the driver for the decision to build the new test facility, and the full capacity of the new test facility will be needed for the work involved.

– Things are moving extremely fast in the wind turbine industry, not least in development of new blades. The fierce price competition between manufacturers is one of the reasons why we’re seeing more development of new blade types for more efficient turbines with larger rotors, since these help cut the cost of kilowatt hours produced. Increased testing capacity is essential if we’re to remain market leaders in blade testing and to keep our growth on track. This is why we’re extremely pleased to have entered into an agreement with Port of Aalborg to build the new, modern test facility. It will double our capacity and give us the opportunity to collaborate more closely with Vestas on blade testing, says Erik Steen Jensen, CEO of BLAEST.

Vestas is the world’s leading manufacturer of wind turbines, with a global market share of more than 22% and its own R&D and blade production. BLAEST has performed full-scale blade testing for Vestas for many years. BLAEST was therefore the natural choice when it came to deciding on key supplier for blade testing. It also helped that BLAEST is ideally situated for transport of test blades, which are manufactured at Vestas’ blade factory in Lem, among other places.

– It’s essential for Vestas to have close partnerships with our suppliers, and we welcome this strengthened collaboration with BLAEST. BLAEST understands how we work and delivers to an extremely high standard. The collaboration underlines the value of a strong network of business partners in Denmark, which has been the wind industry’s global hub for many years. We must maintain this status, and the many green jobs that follow in its wake, by continuing to invest in green R&D and erecting new, modern wind turbines in Denmark so that it makes sense to develop and test new turbines here, says Anders Vedel, CTO at Vestas.

The expansion also means that BLAEST is facing a substantial increase in staff numbers. BLAEST currently has 22 employees, primarily engineers and technicians, and this number is expected to increase to around 35 during the coming year. This will make BLAEST the world’s largest independent test centre for wind turbine blades by far.

Global blade testing hub

With the new test facility, BLAEST doubles its space for testing, and the prospect of more blade tests in the port makes Thomas Kastrup-Larsen, chairman of the board of Aalborg Havn A/S and Mayor of the Municipality of Aalborg, particularly happy. He observes that Aalborg’s East Port has successfully emerged as a world-leading area for blade testing.

– This is truly fantastic, both for Port of Aalborg and for Aalborg in general. A key element of Port of Aalborg’s strategy is to create and facilitate environments for companies working with testing and production of pilot series. It can help put Aalborg at the forefront in areas with great potential, enabling us to generate both growth and more jobs in the town, says Thomas Kastrup-Larsen, and he continues:

– In this context, the collaboration with BLAEST is an outstanding example of our ability to exploit greening to generate growth. As far as I’m aware, due to Siemens Gamesa and BLAEST, we were already the area with the greatest concentration of blade testing facilities in the world, and the new test facility strengthens this position even more. We also have another strong player in the wind turbine industry at the port: Bladt Industries. So, in general, we’re an extremely strong presence in industries dealing with wind energy.

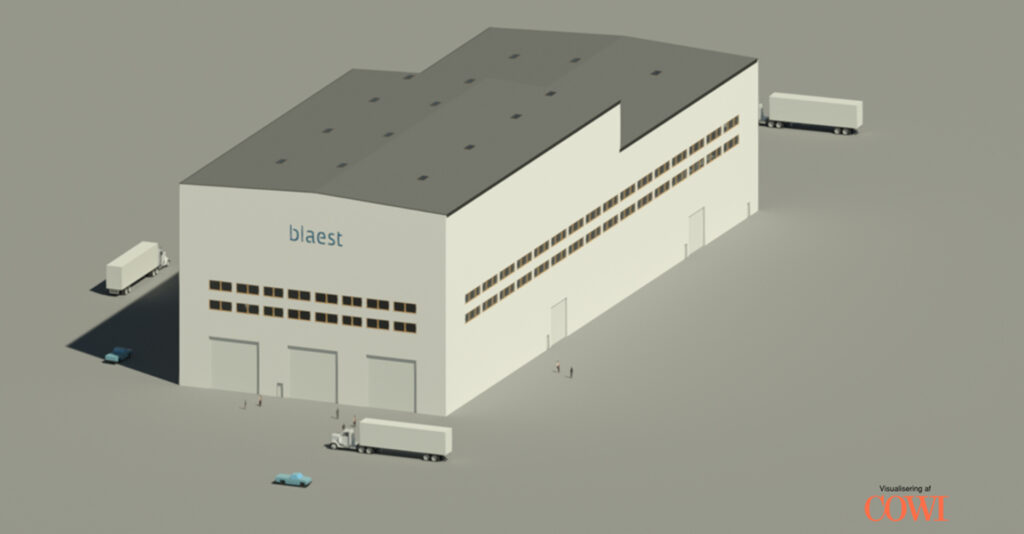

The contract for the new test facility was the subject of an EU tender in the spring, and it was won by an Aalborg company: M. THOMSEN STØTT. AALBORG A/S. The facility is expected to be commissioned as early as January 2020.

Future-proof test facility

The new test facility will be able to test up to 100-metre-long blades. It is equipped with three sophisticated test rigs. These ensure that the comprehensive test programs, which often take more than six months, can be run quickly, efficiently and as safely as possible. Three large gates facing the harbour make it easy to transport the blades in and out. Both the facility itself and the strong foundation under the test rigs are prepared for an expansion, and a further 20 metres can be added if the need should arise in the future.

– Since Vestas focuses its business on onshore wind turbines, the length requirements for the new test facility are not the same as for our existing facility, where we also test blades for offshore wind turbines. However, the trend for both onshore and offshore wind farms is towards larger turbines, so the planned size of the new test facility as well as the potential for expansion mean that we’re well equipped for the future, says Erik Steen Jensen.

In addition to planning the new test facility, BLAEST and Port of Aalborg are in full swing with an extension of the company’s existing test facility. This is where BLAEST will continue to serve its other customers who are basically all of the European blade manufacturers. The existing test facility will be extended by 25 metres to respond to the trend towards blades even longer than 100 metres. This was previously only relevant for offshore wind turbines.

For further details, please contact:

- Erik Steen Jensen, CEO, BLAEST, ext. no. +45 2167 5076 and esj@BLAEST.com

- Thomas Kastrup-Larsen, Mayor of Aalborg and chairman of the board of Port of Aalborg, tel. +45 9931 1500 or tkl-byraad@aalborg.dk

- Press Service: Maja Thordahl Schou, Communication Consultant, Port of Aalborg, ext. no. +45 9930 1528, mobile +45 2261 8308 and mts@aalborghavn.dk